How to Select the Right Diaphragm Valves for Your Industrial Applications

In the industrial landscape, diaphragm valves play a crucial role in ensuring efficient fluid control across various processes. According to a recent market analysis by Research and Markets, the global diaphragm valve market is projected to grow significantly, reaching over USD 6 billion by 2026, highlighting the increasing demand for reliable valve solutions in sectors such as water treatment, pharmaceuticals, and food processing. Selecting the right diaphragm valves is essential for optimizing operational efficiency, ensuring safety, and minimizing maintenance costs. With diverse options available, understanding the key factors such as material compatibility, pressure ratings, and actuation types is imperative for making informed decisions that align with specific industrial applications. This guide aims to provide insightful criteria for selecting diaphragm valves tailored to unique operational needs, thereby enhancing productivity and reliability in your industrial processes.

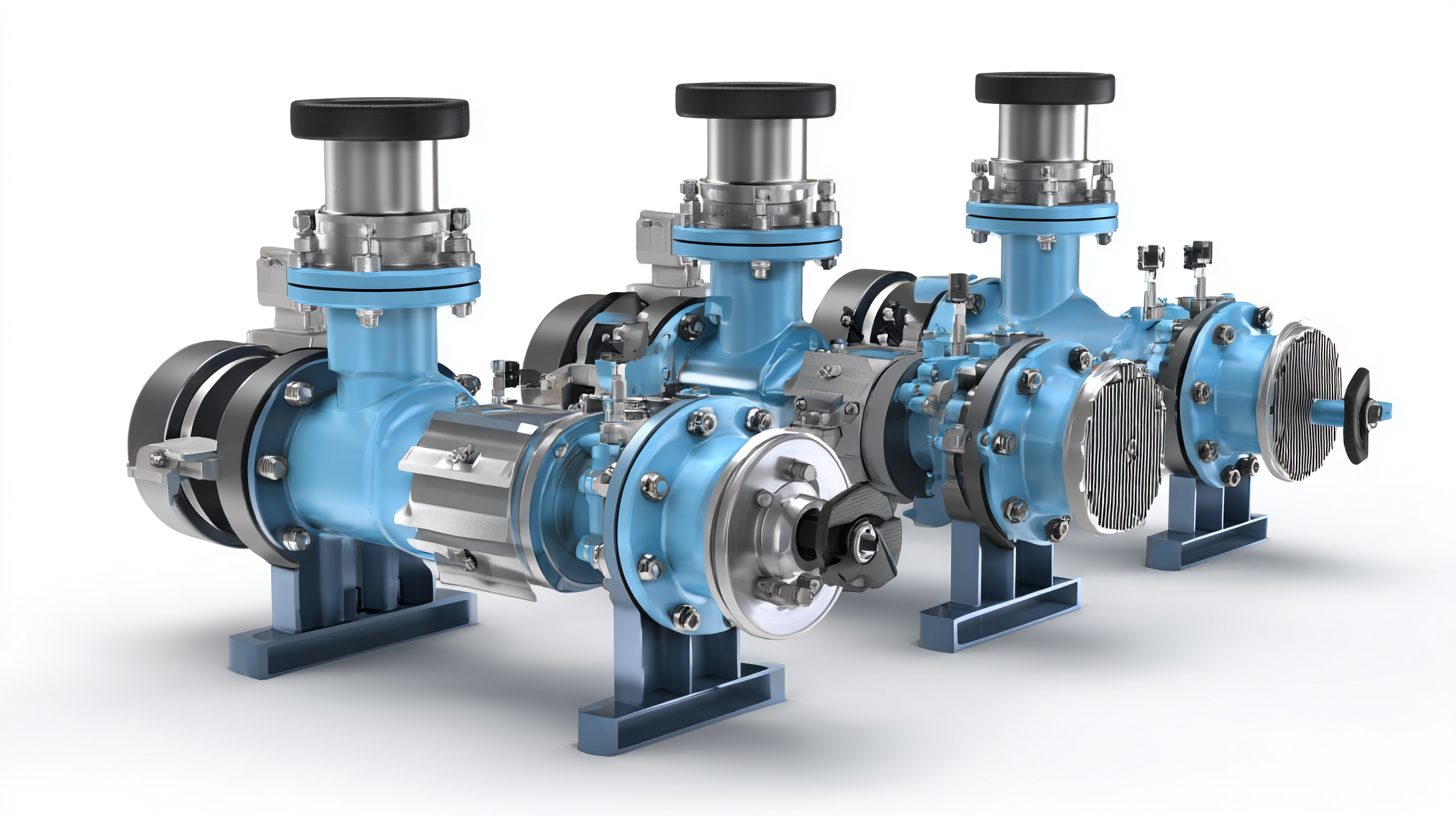

Types of Diaphragm Valves: An Overview of Key Variants

When selecting the right diaphragm valves for industrial applications, understanding the various types available is essential. Diaphragm valves can be broadly categorized into different variants, each designed to meet specific operational needs. Common types include manual diaphragm valves, which offer simplicity and ease of use, and automated variants that enhance process reliability through precise control. Additionally, newer innovations, such as single-use diaphragm valves primarily used in bioprocessing, highlight the trend towards automated and controllable systems that cater to the growing demands in sanitary processes.

The global market for diaphragm valves is witnessing significant growth, particularly with advancements in materials and technologies. For example, the semiconductor diaphragm valve market is projected to grow substantially, reflecting the heightened demand for precision in applications within the semiconductor industry. Similarly, the emergence of certified safety valves, which ensure compliance with drinking water supply standards, illustrates the expanding scope and specialization of diaphragm valves across different sectors. By considering these key variants and their applications, industries can better navigate the options available and select the most suitable diaphragm valves for their specific needs.

Understanding Material Compatibility for Diaphragm Valve Selection

When selecting diaphragm valves for industrial applications, material compatibility is paramount. The materials used in diaphragm valves must withstand the specific chemical environments they will encounter. For example, corrosive substances require valves made from materials such as PTFE or elastomers that resist deterioration. It is essential to understand not only the chemicals being handled but also their concentrations, temperatures, and potential for crystallization or precipitation, all of which can affect valve performance.

Additionally, the operating environment must be taken into account. Factors such as humidity, temperature fluctuations, and exposure to UV light can degrade certain materials over time. Selecting a diaphragm that can withstand these environmental conditions ensures a longer service life and more reliable operation. By closely analyzing the compatibility of valve materials with the fluids they will control, industries can minimize maintenance costs, avoid operational interruptions, and enhance overall system efficiency.

How to Select the Right Diaphragm Valves for Your Industrial Applications - Understanding Material Compatibility for Diaphragm Valve Selection

| Material | Compatible Fluids | Temperature Range (°C) | pH Range | Typical Applications |

|---|---|---|---|---|

| EPDM | Water, Mild Acids, Alkalis | -30 to 120 | 4-9 | Water Treatment, Chemical Processing |

| PTFE | Strong Acids, Solvents | -70 to 260 | 0-14 | Pharmaceuticals, Food Processing |

| Silicone | Food and Beverage, Dairy Products | -50 to 180 | 4-8 | Food Processing, Laboratory Equipment |

| Nitrile | Oils, Fuels, Hydrocarbons | -30 to 100 | 4-9 | Petrochemical, Automotive |

| Viton | Acids, Bases, Fuels | -15 to 204 | 1-14 | Chemical Processing, Oil & Gas |

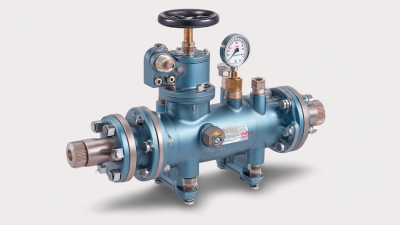

Applications of Diaphragm Valves Across Different Industries

Diaphragm valves are essential components in various industrial applications, providing reliable control of fluid flow across multiple sectors. Their design prevents contamination and leakage, making them ideal for industries such as pharmaceuticals, food and beverage, and water treatment. In the pharmaceutical sector, for instance, diaphragm valves ensure the integrity of sterile environments, while in food processing, they help maintain hygiene standards during production.

When selecting diaphragm valves, it’s crucial to consider the specific requirements of your application. Tips for making the right choice include evaluating the fluid compatibility, temperature, and pressure conditions. Additionally, assess the valve material and diaphragm type to ensure they are suited for your process.

Another important factor is the ease of maintenance. Opt for valves that offer simple disassembly and cleaning procedures. This not only saves time but also extends the lifespan of the equipment. Remember, the right diaphragm valve can significantly enhance efficiency and safety in your operations, contributing to better overall productivity.

Factors Influencing the Selection of Diaphragm Valve Types

When selecting the right diaphragm valves for industrial applications, several key factors should be taken into account. First and foremost is the nature of the fluid being controlled; both its chemical composition and viscosity can dramatically influence the choice of valve materials and design. For instance, if the fluid is corrosive, opting for materials such as PTFE or specific alloys is essential to ensure durability and reliable operation.

When selecting the right diaphragm valves for industrial applications, several key factors should be taken into account. First and foremost is the nature of the fluid being controlled; both its chemical composition and viscosity can dramatically influence the choice of valve materials and design. For instance, if the fluid is corrosive, opting for materials such as PTFE or specific alloys is essential to ensure durability and reliable operation.

Another critical aspect is the operating pressure and temperature. Diaphragm valves are available in various pressure ratings and temperature ranges, so it's imperative to select a valve that can withstand the specific conditions of your application. Additionally, consider the frequency of operation; valves designed for frequent cycling may require different designs than those used sporadically.

Tips: Always consult with manufacturers or technical experts about compatibility with your specific application. If possible, test different diaphragm valves in a controlled environment to observe their performance before making a final decision. Lastly, don't overlook the importance of installation and maintenance; proper care can significantly extend the lifespan and efficiency of the valves in your system.

Best Practices for Installing and Maintaining Diaphragm Valves

When it comes to installing and maintaining diaphragm valves in industrial applications, adhering to best practices is essential for ensuring optimal performance and longevity. One of the key tips for installation is to ensure that the valve is aligned correctly with the pipeline to prevent any undue stress. Misalignment can lead to leaks and premature wear, affecting the overall efficiency of the system. Additionally, consider the environmental factors, such as temperature and fluid characteristics, that might affect the valve's performance.

Regular maintenance is equally critical. It is recommended to frequently inspect diaphragm valves for signs of wear or damage. A proactive approach includes checking seals and diaphragms for cracks or wear, as these components are vital for maintaining seal integrity. To extend the lifespan of valves, always keep the surrounding area clean and free from debris. Implement a pressure management system to monitor and control the pressure within the system, which can prevent overheating and potential damage during operation. Following these best practices can significantly enhance the reliability and effectiveness of diaphragm valves in various applications.

Diaphragm Valve Selection and Maintenance Insights

This chart illustrates the key factors affecting the selection and maintenance of diaphragm valves in industrial applications. The data shows the importance of various criteria in the decision-making process.

Related Posts

-

Ultimate Guide to Sourcing the Best Pressure Control Valves for Your Needs

-

The Definitive Guide to Sourcing Top Quality Small Pneumatic Valves from Trusted Suppliers

-

Emerging Trends in Pressure Valve Technology for 2025 Shaping Industry Standards

-

Unlocking Precision in Fluid Dynamics with the Best Liquid Flow Control Valve Technical Specifications and Best Practices

-

Exploring Innovative Alternatives to the Best Small Pneumatic Valves for Your Industrial Needs

-

Choosing the Right Manufacturer for High Quality Air Solenoid Valve Solutions