7 Essential Features of Small Pneumatic Valves You Should Know About

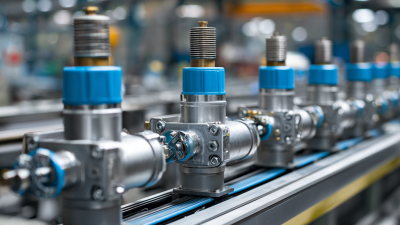

In the ever-evolving landscape of industrial automation, small pneumatic valves play a critical role in enhancing system efficiency and reliability. According to a report by Research and Markets, the global pneumatic valve market is expected to grow significantly, driven by the increasing adoption of automation across various sectors. Small pneumatic valves, in particular, cater to applications where minimal space and precision control are essential. These compact devices offer numerous benefits, including reduced energy consumption, improved response times, and enhanced operational safety. As the demand for more compact and efficient valve solutions rises, understanding the essential features of small pneumatic valves becomes crucial for engineers and decision-makers aiming to optimize their systems. In this blog, we will explore seven key features of small pneumatic valves that not only augment performance but also contribute to the overall success of automated processes.

Understanding the Core Functionality of Small Pneumatic Valves

Small pneumatic valves play a crucial role in a variety of applications, particularly in automation and control systems. Their core functionality revolves around regulating airflow and pressure, which is essential for efficient operation in machinery. Recent advancements, such as the introduction of a single-coil-driven tristable electromagnetic mini valve with three stable working states, demonstrate how innovation can enhance the capabilities of pneumatic systems. These valves not only optimize performance but also reduce energy consumption, supporting the growing demand for efficiency in industrial processes.

Moreover, manufacturers have been expanding their product ranges to include user-friendly designs, like manually and mechanically operated pneumatic valves. These new models offer durability and reliability crucial for applications demanding high precision. A report from industry experts notes that the global market for pneumatic valves is expected to grow significantly, driven by increasing automation in various sectors. As businesses strive for higher productivity and lower operational costs, understanding the core functionality of small pneumatic valves becomes pivotal for engineers and technicians looking to enhance system performance.

Key Design Considerations for Optimal Performance in Pneumatic Systems

When designing pneumatic systems, small pneumatic valves play a crucial role in ensuring optimal performance. Understanding key design considerations, such as size, type, and material, can significantly enhance efficiency and reliability. For instance, the selection of valve materials should account for factors like pressure, temperature, and compatibility with the media being controlled. These aspects are essential, especially in applications requiring precision and durability.

When designing pneumatic systems, small pneumatic valves play a crucial role in ensuring optimal performance. Understanding key design considerations, such as size, type, and material, can significantly enhance efficiency and reliability. For instance, the selection of valve materials should account for factors like pressure, temperature, and compatibility with the media being controlled. These aspects are essential, especially in applications requiring precision and durability.

Tip: Always choose valves that are rated for the specific application to avoid premature failure. Additionally, consider the installation space when selecting valve size;

Another important consideration is the valve's operating mechanism. Whether using solenoid or pneumatic actuation, the choice can affect response times and overall system functionality. Implementing appropriate design strategies, like optimizing airflow and minimizing dead volumes, can further enhance system performance.

Tip: Regular maintenance and monitoring of valve performance can help catch issues early, ensuring continuous operation and preventing costly downtimes.

The Importance of Material Selection for Durability and Efficiency

When selecting small pneumatic valves, the choice of materials plays a crucial role in determining both durability and operational efficiency. Valves are subjected to various environmental conditions and pressures, making it essential that the materials used can withstand wear and tear. For instance, stainless steel and brass are often preferred for their corrosion resistance and strength, ensuring that the valve maintains its integrity over time. Using the right material not only extends the lifespan of the valve but also minimizes the risk of leaks and failures, ultimately leading to greater reliability in pneumatic applications.

Additionally, the efficiency of a small pneumatic valve is heavily influenced by material selection. Different materials have varying thermal and chemical resistance, which can affect the valve's performance at high pressures or extreme temperatures. For example, using polymers with high wear resistance can minimize friction and enhance flow rates, thereby improving overall system efficiency. By carefully considering the material properties, designers can optimize the functionality of pneumatic systems, ensuring they operate smoothly and efficiently for longer periods. Proper material selection is, therefore, not just a matter of durability but a strategic decision impacting the entire pneumatic system's effectiveness.

7 Essential Features of Small Pneumatic Valves

This chart illustrates the distribution of key features to consider when selecting small pneumatic valves, emphasizing the importance of material selection for durability and efficiency.

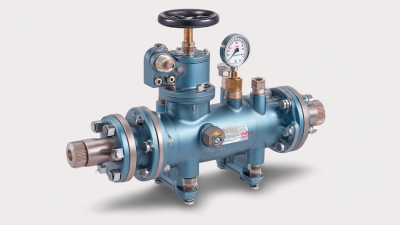

Exploring Control Methods: Manual vs. Automated Small Pneumatic Valves

When considering small pneumatic valves, one critical aspect to explore is the control method—manual versus automated systems. Manual small pneumatic valves require skilled operators to adjust the flow and pressure, ensuring that processes are managed effectively. While this approach can provide a hands-on level of control, it is often resource-intensive and may lead to inefficiencies if not handled proficiently. The need for continuous oversight can also be a drawback in environments that demand rapid adjustments and high throughput.

On the other hand, automated small pneumatic valves offer significant advantages in terms of reliability and operational efficiency. With the rise of electric actuators, which are gaining traction across various industries, automation facilitates real-time adjustments and enhances system responsiveness. This transition is particularly notable in sectors such as oil and gas, aerospace, and wastewater management, where precision and speed are paramount. As the market for electric actuators continues to grow, integrating automated control methods into pneumatic valve systems can lead to optimized performance, reduced labor costs, and improved safety in operations.

Maintenance Tips to Extend the Lifespan of Your Pneumatic Valves

When it comes to maintaining small pneumatic valves, regular upkeep is essential for extending their lifespan and ensuring optimal performance. One of the most crucial maintenance tips is to conduct routine inspections for signs of wear and tear. Check for any leakage, unusual noises, or inconsistent actuator performance. Addressing these issues early can prevent more extensive damage and costly repairs down the line. Additionally, it's important to keep the valves clean. Contaminants can impair valve function, so using appropriate cleaning agents and techniques suited to the materials of your valves can significantly enhance their operational life.

Lubrication also plays a crucial role in pneumatic valve maintenance. Using the right type of lubricant can reduce friction and wear on moving parts, ensuring smooth operation. Be sure to follow the manufacturer’s recommendations for both the type and frequency of lubrication. Moreover, maintaining a proper operating environment is essential. Avoid exposure to extreme temperatures, moisture, or corrosive substances that can negatively impact valve performance. By implementing these maintenance practices, you can enhance the durability and efficiency of small pneumatic valves, ensuring they perform reliably in your applications for years to come.

Related Posts

-

Exploring Innovative Alternatives to the Best Small Pneumatic Valves for Your Industrial Needs

-

The Definitive Guide to Sourcing Top Quality Small Pneumatic Valves from Trusted Suppliers

-

2025 Market Trends in Pneumatic Valves for Global Buyers

-

7 Effective Tips to Optimize Pneumatic Flow Valve Performance

-

Choosing the Right Manufacturer for High Quality Air Solenoid Valve Solutions

-

Emerging Trends in Pressure Valve Technology for 2025 Shaping Industry Standards