Essential Factors to Consider When Selecting the Best Pneumatic Control Valve

In the rapidly evolving landscape of industrial automation, the selection of the right pneumatic control valve has become a critical determinant of operational efficiency and reliability. As industries increasingly seek to enhance their production capabilities, reports indicate that the global pneumatic control valve market is projected to reach USD 9.14 billion by 2027, growing at a CAGR of 5.8% from 2020. This surge reflects the rising demand for precision control in various applications, including manufacturing, oil and gas, and water treatment. Choosing the right pneumatic control valve not only influences system performance but also affects overall product quality, making it essential for companies to consider key factors such as material compatibility, pressure ratings, and valve response time. As China expands its footprint in global markets, the emphasis on high-quality pneumatic control valves is more pronounced, underscoring how quality-driven innovations can lead to competitive advantages and greater market share.

Key Characteristics to Look for in a High-Quality Pneumatic Control Valve Manufacturer

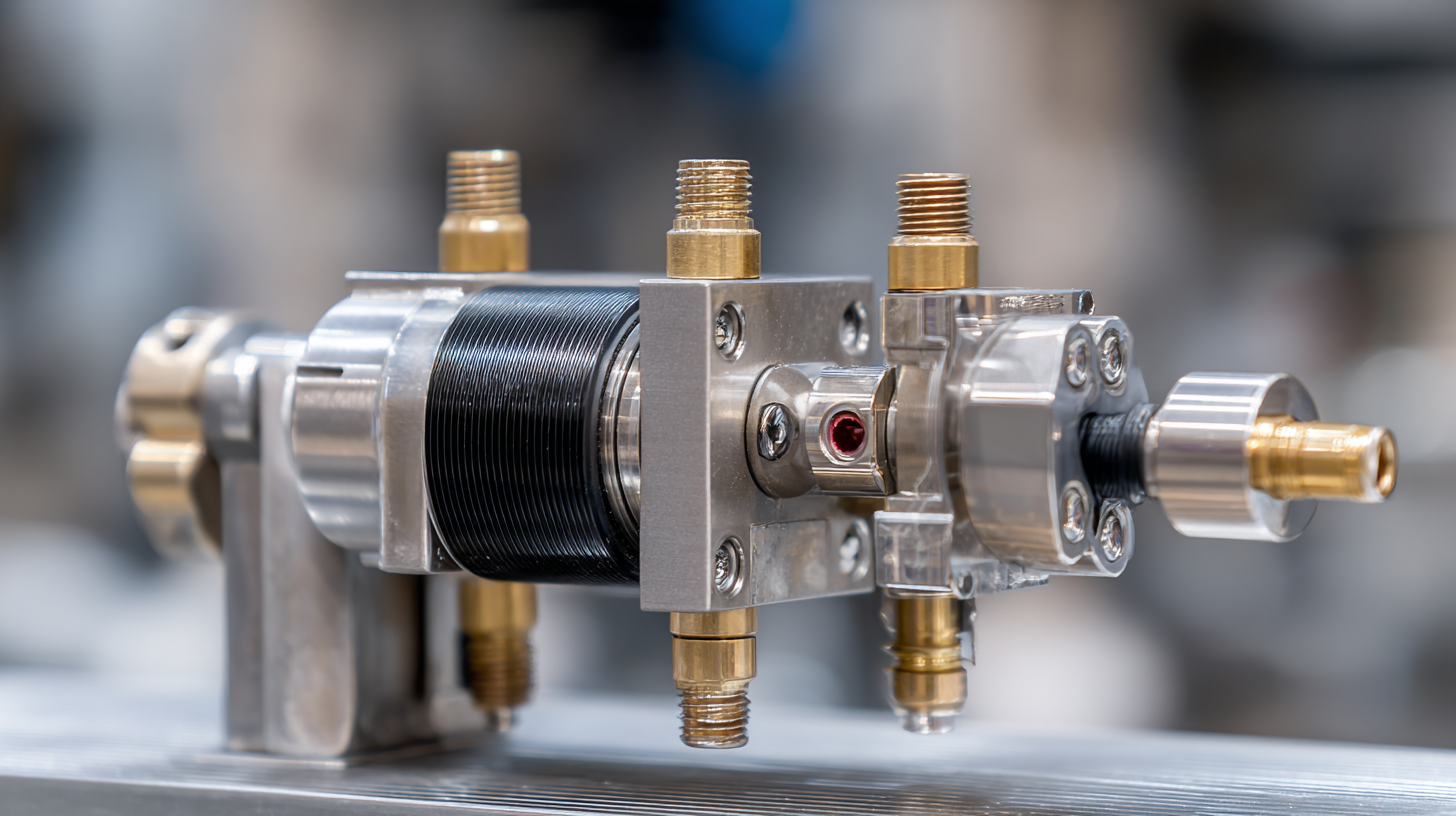

When selecting a high-quality pneumatic control valve manufacturer, several key characteristics are essential to ensure optimal performance and reliability. Firstly, quality assurance processes must be a focal point for the manufacturer. Look for a company that adheres to stringent industry standards and possesses certifications such as ISO 9001, which signifies a commitment to quality management practices and continuous improvement.

Another critical factor is the manufacturer's experience and expertise in the field. Companies with a long track record of engineering excellence and innovation are often better equipped to meet diverse customer needs. Additionally, consider their customer service and support capabilities. A manufacturer that offers comprehensive technical support and timely service can greatly enhance the overall product experience, minimizing downtime and ensuring that any issues are promptly addressed.

Lastly, examine the range of materials and technologies used in the valve's construction. A reputable manufacturer should utilize high-grade materials that offer durability and resistance to wear and corrosion, while also providing advanced features such as smart diagnostics for improved control. By focusing on these characteristics, you can make an informed choice that aligns with your pneumatic system requirements.

Understanding Industry Certifications and Standards for Valve Manufacturing

When selecting the best pneumatic control valve, understanding industry certifications and standards is crucial for ensuring reliability and performance. Certifications such as ISO 9001, which pertains to quality management systems, indicate that the manufacturer adheres to rigorous quality control processes. This can provide confidence in the consistency of valve performance and durability. Moreover, industry-specific standards, such as those set by the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO), offer guidelines for the design and testing of valves, promoting safety and efficiency in their applications.

Additionally, valves often require compliance with environmental regulations and safety standards, such as the ATEX and CE markings, which signify that they are suitable for use in potentially explosive atmospheres or meet the European Union's safety directives, respectively. By carefully considering these certifications and standards during the selection process, engineers and procurement professionals can minimize risks associated with valve failures and ensure optimal operation within their systems. Ultimately, investing time in understanding these factors can lead to more informed decisions and enhance the overall reliability of pneumatic control systems.

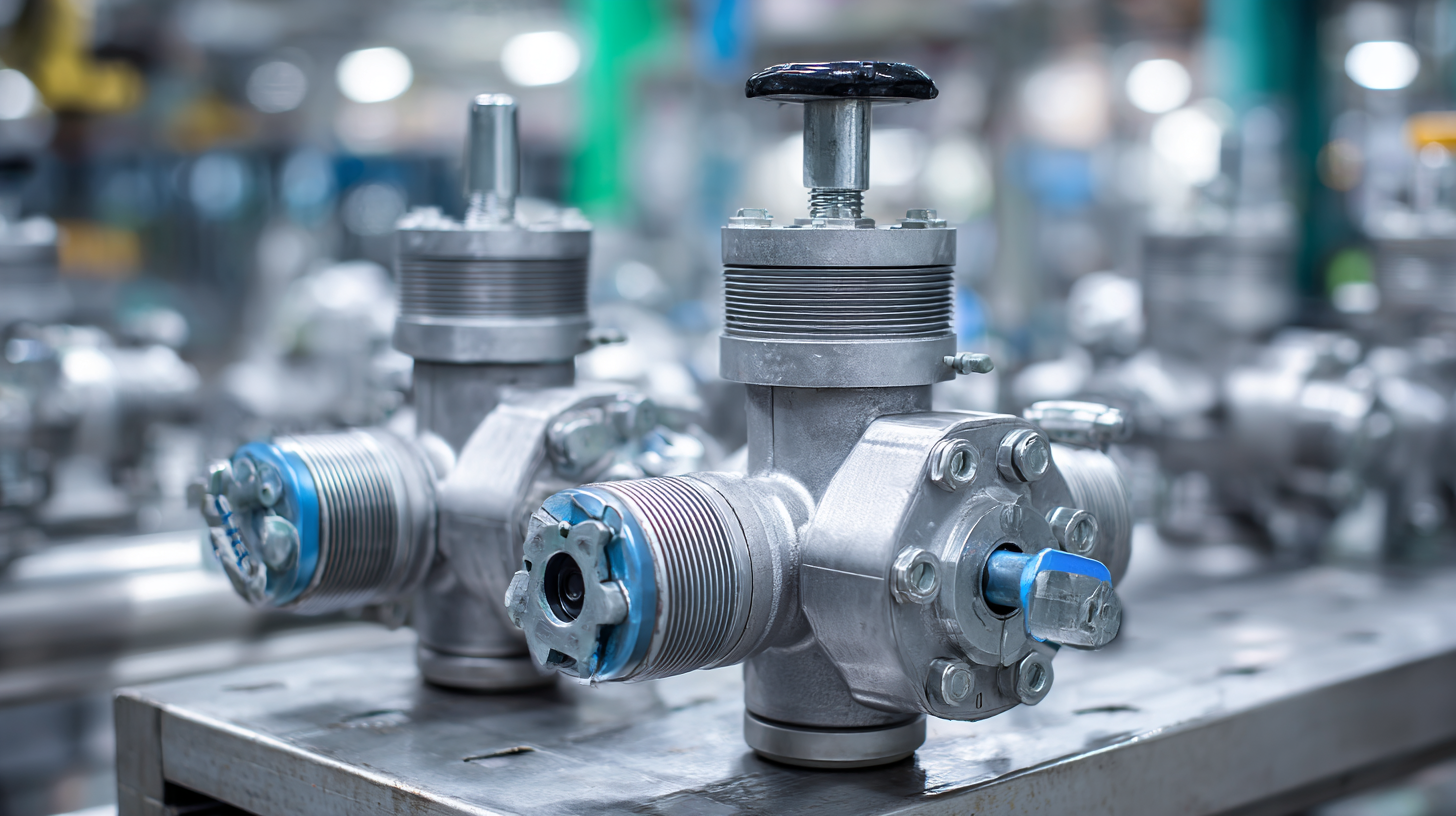

The Importance of Material Quality in Pneumatic Control Valve Production

When selecting a pneumatic control valve, the importance of material quality cannot be overstated. The durability and performance of a valve are significantly influenced by the materials used in its construction. High-quality materials ensure that the valve can withstand extreme temperatures, corrosive substances, and high pressures without degrading. This not only extends the lifespan of the valve but also reduces maintenance costs and potential downtime in operations.

**Tip:** When evaluating a valve's material quality, look for certifications from recognized standards organizations. Materials such as stainless steel and specialized plastics often offer enhanced resistance to both corrosion and wear. Always inquire about the material's compatibility with the specific media it will control to ensure optimal performance.

Moreover, the manufacturing process plays a critical role in the overall quality of pneumatic control valves. Attention to detail in machining and assembly can prevent leaks and improve the valve's responsiveness. Manufacturers that prioritize precision engineering typically produce valves that perform reliably under a variety of conditions.

**Tip:** Research the manufacturer's reputation and their production techniques. Choosing valves from well-established companies that utilize advanced technology can lead to better long-term investment returns. Always request detailed specifications and testing results to ensure the selected valve meets your operational needs.

Evaluating Manufacturer Reputation and Customer Testimonials

When selecting the best pneumatic control valve, it is crucial to evaluate manufacturer reputation and customer testimonials as they serve as the backbone of a product's reliability and performance. A well-established manufacturer typically has a history of producing high-quality valves that meet industry standards. Researching the manufacturer’s background, including their experience, certifications, and innovation in product design, can offer insights into their commitment to excellence. Manufacturers with a strong reputation are often more transparent about their manufacturing processes and quality control measures, giving customers confidence in their products.

Customer testimonials provide invaluable firsthand accounts of a valve’s performance in real-world applications. Reading reviews from users who have experienced a product can reveal important details about reliability, ease of installation, and overall satisfaction. Look for testimonials that highlight the valve's efficiency and durability under various operating conditions, as well as the support provided by the manufacturer post-purchase. A combination of positive feedback and credible manufacturer reputations can significantly influence purchasing decisions, ensuring that you choose a pneumatic control valve that meets your needs effectively.

Essential Factors in Selecting the Best Pneumatic Control Valve

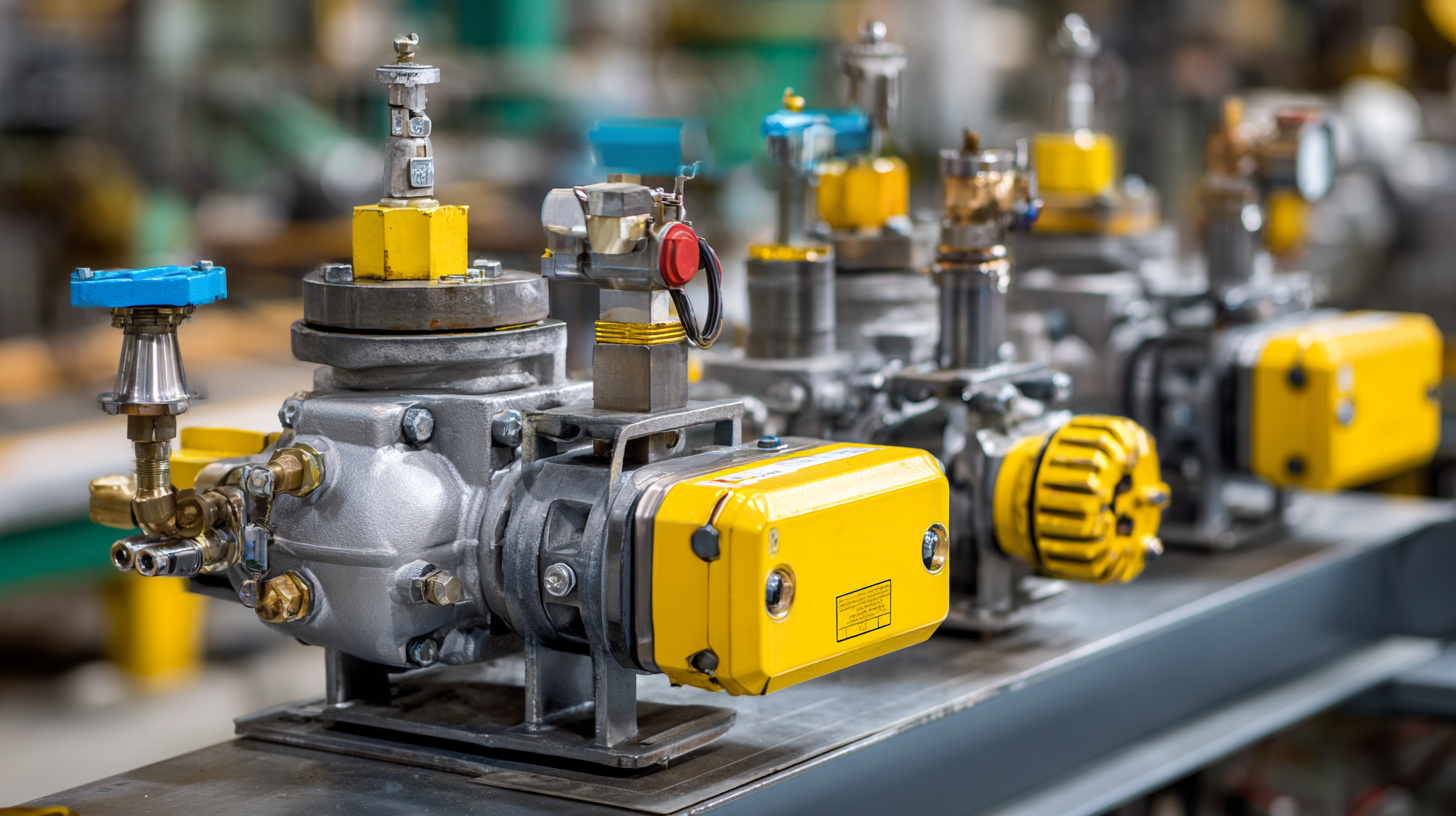

Assessing Technological Innovations in Pneumatic Control Valve Design

When evaluating pneumatic control valves, it's crucial to focus on the technological innovations that enhance their performance and reliability. Recent advancements in materials, such as the adoption of lightweight composites and advanced polymers, have significantly increased corrosion resistance and operational longevity. According to a report by Research and Markets, the global pneumatic control valves market is projected to grow at a CAGR of 6.1% from 2021 to 2026, driven largely by innovations that improve efficiency and reduce energy consumption in industrial applications.

Moreover, smart valve technologies, integrated with IoT and real-time monitoring systems, are revolutionizing how pneumatic control valves are managed. The integration of artificial intelligence in valve diagnostics is becoming more prevalent, allowing for predictive maintenance that minimizes downtime and operational costs. A study by Fortune Business Insights highlights that the smart valve segment is expected to see a substantial increase, with revenues potentially reaching $1.5 billion by 2025. These innovations not only optimize process control but also align with increasing regulatory demands for efficiency and sustainability, making the selection of the right pneumatic control valve ever more vital.