Tailored Solutions for Enhancing Efficiency with Advanced Solenoid Valves in Industrial Applications

In the rapidly evolving industrial landscape, the demand for enhanced efficiency and precision in automated systems has never been more critical. A recent report by MarketsandMarkets indicates that the global solenoid valves market is projected to reach USD 3.9 billion by 2025, growing at a CAGR of 6.3% from 2020. This growth is driven by the increasing need for advanced solutions capable of optimizing performance across various applications, including manufacturing, chemical processing, and HVAC systems. Solenoid valves have emerged as pivotal components, enabling the automation of fluid control systems with remarkable accuracy and reliability. By leveraging tailored solutions that integrate state-of-the-art solenoid valve technology, industries can significantly boost operational efficiency, reduce waste, and enhance overall productivity, ultimately resulting in greater competitiveness in today’s market.

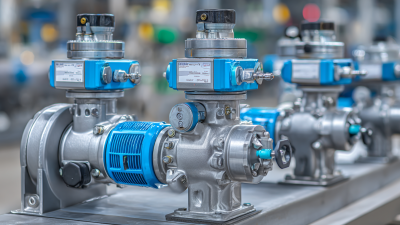

Types of Advanced Solenoid Valves and Their Industrial Applications

Advanced solenoid valves play a crucial role in various industrial applications, driving improvements in efficiency and reliability. These valves, which convert electrical energy into mechanical movement to control fluid flow, are integral to systems ranging from automations in manufacturing to pneumatic and hydraulic applications. The hydraulic valve market alone is projected to reach USD 15.87 billion by 2034, with a growth rate of 6.32% CAGR, highlighting the increasing demand for sophisticated valve technologies across sectors.

Different types of advanced solenoid valves serve specific industrial needs. For instance, innovations such as controlled pneumatics technology leverage digital closed-loop control to optimize operational precision in applications like welding and assembly lines. Additionally, advanced sealing solutions developed for high-pressure and chemically demanding environments further enhance the performance of solenoid valves in industries like automotive, where the market is on track to grow from USD 25.1 billion in 2022 to USD 28.2 billion by 2027. This trend underscores the vital role of engineered solutions in maintaining productivity and safeguarding system integrity.

Types of Advanced Solenoid Valves and Their Industrial Applications

This chart illustrates the efficiency improvement across various industries using advanced solenoid valves, showcasing the demand and applications in sectors such as Automotive, Oil & Gas, Water Management, and HVAC.

Key Features of Solenoid Valves That Enhance Operational Efficiency

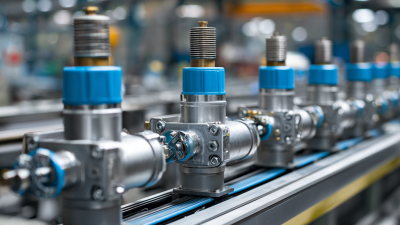

Enhancing operational efficiency in industrial applications is crucial, and

advanced solenoid valves play a key role in achieving this goal. These valves are designed to offer

precise control over fluid movements while ensuring reliability and durability. Key features such as quick response times,

low power consumption, and the ability to handle high pressures contribute to their effectiveness.

For instance, direct-acting solenoid valves provide immediate fluid flow control, which is essential in processes requiring rapid adjustments.

Additionally, the availability of various materials, such as

stainless steel and

corrosion-resistant plastics, ensures that these valves can operate effectively in diverse environments.

Enhancing operational efficiency in industrial applications is crucial, and

advanced solenoid valves play a key role in achieving this goal. These valves are designed to offer

precise control over fluid movements while ensuring reliability and durability. Key features such as quick response times,

low power consumption, and the ability to handle high pressures contribute to their effectiveness.

For instance, direct-acting solenoid valves provide immediate fluid flow control, which is essential in processes requiring rapid adjustments.

Additionally, the availability of various materials, such as

stainless steel and

corrosion-resistant plastics, ensures that these valves can operate effectively in diverse environments.

Moreover, the integration of advanced solenoid valves can significantly impact a facility’s overall productivity. Their ability to automate processes not only minimizes human error but also enhances safety conditions in industrial settings. With the growing investment in renewable energy infrastructure, the demand for specialized solenoid valves that can withstand the unique challenges of solar applications is on the rise. As industries increasingly seek tailored solutions to boost efficiency, investing in high-quality solenoid valves could be a decisive factor in optimizing operations and maximizing output.

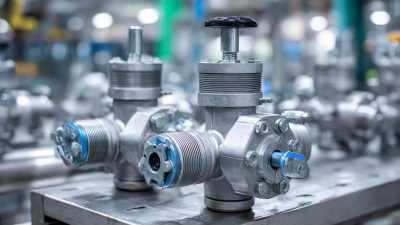

The Role of Customization in Selecting Solenoid Valves for Specific Needs

In today’s industrial landscape, the selection of solenoid valves plays a pivotal role in enhancing efficiency and optimizing operations. Customizing solenoid valves to meet specific operational needs is critical; research indicates that tailored solutions can improve system efficiency by over 30%. According to a report by MarketsandMarkets, the global solenoid valve market is projected to reach $7.5 billion by 2025, underscoring the increasing demand for innovative and customized valve solutions that cater to diverse industrial applications.

Customization not only addresses unique process requirements but also ensures compatibility with varying media types, pressure ranges, and environmental conditions. For instance, the ability to design solenoid valves that withstand harsh conditions can significantly reduce downtime and maintenance costs. Engineering experts emphasize that by leveraging advanced materials and precise engineering, industries can achieve a reduction in energy consumption by as much as 25%. This highlights the importance of selecting the right solenoid valves, which can be tailored to enhance performance, reliability, and sustainability in industrial processes.

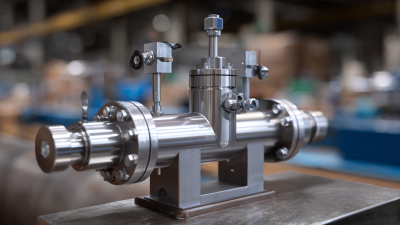

Comparative Analysis of Solenoid Valves Versus Traditional Control Valves

The choice between solenoid valves and traditional control valves plays a crucial role in enhancing efficiency within hydraulic systems. Solenoid valves, known for their rapid response times and precise control capabilities, offer a significant advantage in applications that require quick actuation and minimization of lag. This is particularly relevant in sectors where high power-to-weight ratios are paramount, allowing for more streamlined operations without sacrificing performance.

In contrast, traditional control valves, while established and reliable, often face limitations in adaptability and operational speed. Their mechanical nature can result in slower response times, which may hinder overall system efficiency. The integration of advanced solenoid valves into industrial applications not only optimizes the control and automation of processes but also facilitates greater energy savings, contributing to the industry's push towards more sustainable practices. As the market evolves, understanding the comparative advantages of these valve types will be essential for companies seeking tailored solutions to meet their operational needs.

Case Studies: Successful Implementation of Solenoid Valves in Various Industries

In recent years, the implementation of advanced solenoid valves has transformed various industrial sectors, enhancing operational efficiency and reliability. Several case studies demonstrate the versatility of these components. For instance, in the automotive industry, solenoid valves have streamlined fuel injection systems, ensuring precise control of fuel flow and contributing to better engine performance and lower emissions. Similarly, in the pharmaceutical sector, solenoid valves facilitate accurate fluid dispensing, which is crucial for maintaining quality standards in drug manufacturing processes.

**Tip:** When selecting solenoid valves for specific applications, consider the compatibility with the fluids being used, temperature ranges, and pressure requirements. This will ensure optimal performance and longevity of the valves.

Another example can be seen in the food and beverage industry, where solenoid valves are employed in automated bottling systems. They help regulate the flow of liquids and gases, significantly reducing waste and improving production time. A beverage manufacturer reported a 20% increase in efficiency after integrating solenoid valves into their packaging line, highlighting their impact on operational success.

**Tip:** Regular maintenance and timely replacement of solenoid valves can prevent unexpected downtime and ensure consistent production levels. Implementing a predictive maintenance schedule will further enhance the reliability of your processing systems.

Related Posts

-

How to Choose the Best Solenoid Valves for Your Industrial Applications

-

Top 10 Applications of the Best Pneumatic Solenoid Valves in Industrial Automation

-

2025 Market Trends in Pneumatic Valves for Global Buyers

-

Choosing the Right Manufacturer for High Quality Air Solenoid Valve Solutions

-

Essential Factors to Consider When Selecting the Best Pneumatic Control Valve

-

Unlocking Precision in Fluid Dynamics with the Best Liquid Flow Control Valve Technical Specifications and Best Practices