How to Efficiently Utilize Air Flow Valves for Optimal System Performance

In today's increasingly complex HVAC systems, the efficient utilization of air flow valves is critical for achieving optimal system performance. According to the National Institute of Standards and Technology, approximately 30% of energy consumed in commercial buildings can be attributed to HVAC inefficiencies, highlighting the need for effective airflow management.

Air flow valves play a pivotal role in regulating air distribution, ensuring that conditioned air reaches its intended spaces while minimizing energy waste. A report by the American Society of Heating, Refrigerating and Air-Conditioning Engineers indicates that proper selection and installation of air flow valves can improve system efficiency by up to 20%.

As organizations strive for sustainability and cost-efficiency, understanding how to effectively implement air flow valves becomes essential for enhancing overall system performance and reducing operational costs.

Air flow valves play a pivotal role in regulating air distribution, ensuring that conditioned air reaches its intended spaces while minimizing energy waste. A report by the American Society of Heating, Refrigerating and Air-Conditioning Engineers indicates that proper selection and installation of air flow valves can improve system efficiency by up to 20%.

As organizations strive for sustainability and cost-efficiency, understanding how to effectively implement air flow valves becomes essential for enhancing overall system performance and reducing operational costs.

Understanding the Functionality of Air Flow Valves in HVAC Systems

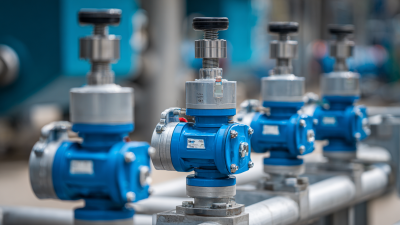

Air flow valves play a crucial role in the performance and efficiency of HVAC systems. They are designed to regulate and direct the flow of air in various applications, ensuring that heating, ventilation, and air conditioning processes operate optimally. According to the U.S. Department of Energy, effectively utilizing air flow valves can lead to a 20-30% increase in energy efficiency in HVAC systems, significantly reducing operational costs.

Understanding the functionality of air flow valves begins with their ability to balance air distribution across different zones. This is vital as uneven air flow can lead to discomfort and unnecessary energy consumption. By employing advanced technologies like modulating control valves, facilities can achieve a more precise regulation of air supply, enhancing occupant comfort while also minimizing energy waste. The ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers) reports that proper air flow management can increase system longevity by preventing strain on equipment, contributing to both sustainability and cost savings in the long term.

Selecting the Right Type of Air Flow Valve for Your Application

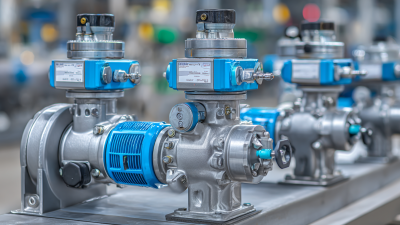

When selecting the right type of air flow valve for your application, it is essential to consider the specific requirements of your system, including the flow rate, pressure, and medium type. According to a report by the National Association of Manufacturers, efficient valve selection can enhance overall system performance by up to 30%. This optimization not only improves energy efficiency but also extends the lifespan of the equipment through reduced wear and tear.

There are various types of air flow valves, including globe valves, butterfly valves, and ball valves, each with unique benefits suited to different applications. For instance, globe valves are known for their excellent throttling capabilities, making them ideal for applications requiring precise flow control. On the other hand, butterfly valves offer a compact design and lightweight construction, which can lead to easier installation and maintenance, particularly in large industrial settings. By utilizing industry data and performing a thorough analysis of your specific requirements, you can significantly enhance your system’s operational efficiency.

Techniques for Proper Installation of Air Flow Valves for Maximum Efficiency

Proper installation of air flow valves is crucial for maximizing system efficiency. To begin with, it’s essential to select the right type of valve for your specific application, considering factors such as air volume, pressure ratings, and the system configuration. Ensuring accurate sizing of the valve can prevent issues like over or under-pressurization, which can lead to inefficiencies in airflow management. Before installation, all components should be inspected for cleanliness and integrity to avoid workflow disruptions.

During installation, following the manufacturer's guidelines is key to achieving optimal performance. Positioning the valves correctly within the airflow path can help maintain balanced air distribution, reducing energy consumption and enhancing overall system efficiency. It’s advisable to install the valves at strategic points, such as near terminal units and duct turns, to minimize turbulence and pressure drops. Additionally, using proper sealing techniques around joints and connections prevents leakage, ensuring that the system operates at peak performance while reducing unnecessary operational costs.

Regular maintenance checks can further enhance the longevity and effectiveness of air flow valves, contributing to sustained efficiency.

Regular Maintenance Practices to Enhance Air Flow Valve Performance

Regular maintenance practices are essential in enhancing the performance of air flow valves, which play a critical role in optimizing system efficiency. According to the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), maintaining a clean system can improve energy efficiency by up to 30%. This highlights the importance of routine inspections and cleaning of air flow valves to remove any accumulated dirt or debris that may hinder airflow and lead to decreased performance.

Additionally, data from the U.S. Department of Energy indicates that regular maintenance can extend the lifespan of air flow valves by up to 50%. Routine checks should include inspecting seals for wear and ensuring that actuators operate smoothly. Implementing a preventive maintenance schedule not only mitigates unexpected failures but also saves on costly repairs and downtime. Each of these practices contributes significantly to the overall efficiency and reliability of HVAC systems, ensuring they operate at optimal capacity.

How to Efficiently Utilize Air Flow Valves for Optimal System Performance - Regular Maintenance Practices to Enhance Air Flow Valve Performance

| Maintenance Practice | Frequency | Benefits | Notes |

|---|---|---|---|

| Visual Inspection | Monthly | Early detection of leaks or blockages | Look for rust, corrosion, and unusual noises |

| Cleaning | Quarterly | Improved airflow and efficiency | Use appropriate cleaning solutions |

| Calibration | Annually | Ensures accurate flow measurements | Follow manufacturer specifications |

| Component Replacement | As needed | Restores system efficiency | Track wear and tear during inspections |

Troubleshooting Common Air Flow Valve Issues for Improved System Efficiency

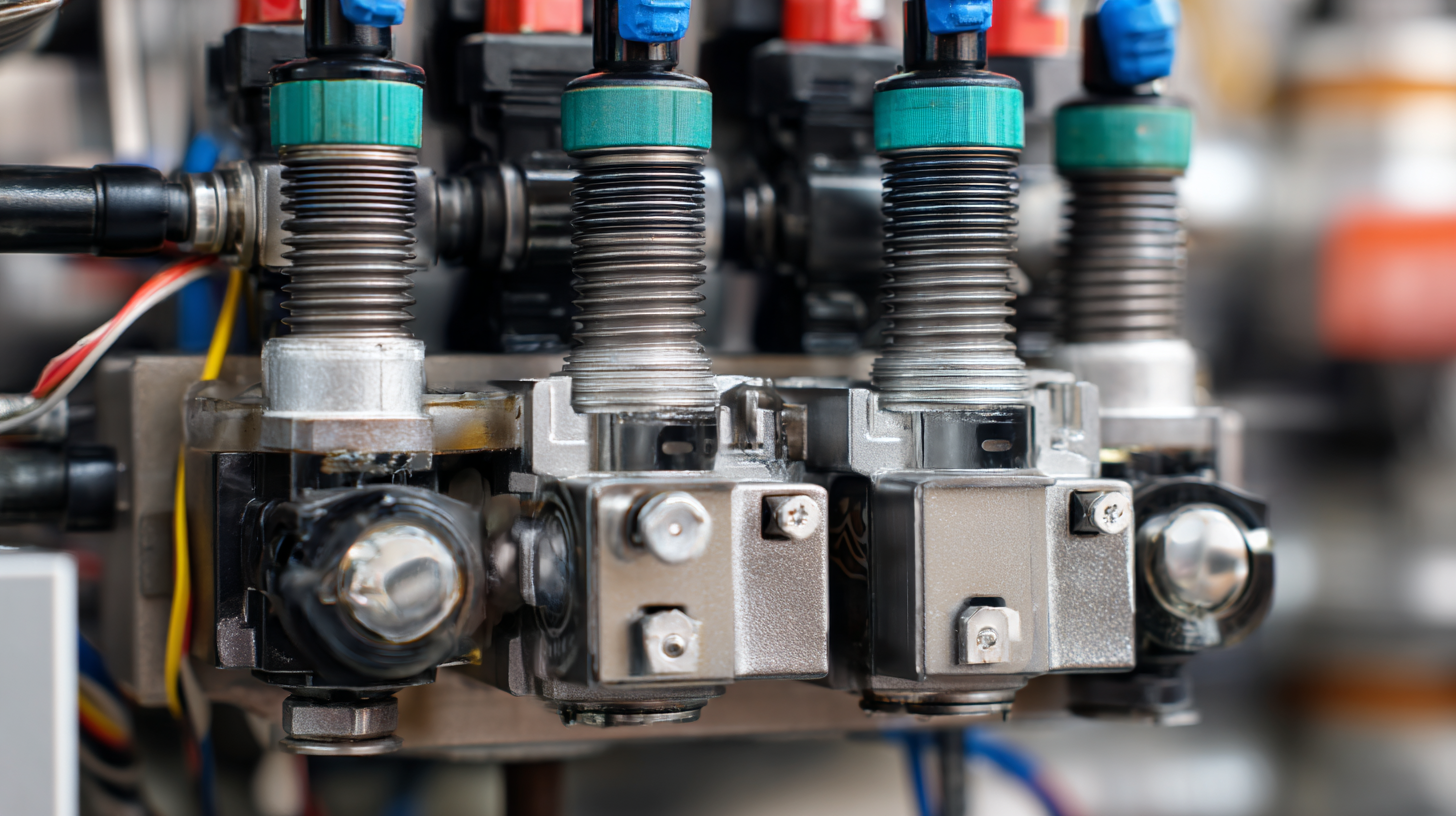

Air flow valves play a crucial role in maintaining optimal system performance, particularly in applications like turbocharged engines.

However, various failure modes can impact their efficiency. Common issues include restrictions in air flow, valve misalignment, and control system malfunctions. By systematically measuring air flow, power requirements, and temperature, these problems can be diagnosed.

For instance, a drop in power output may indicate an obstruction or malfunctioning valve that requires immediate attention.

However, various failure modes can impact their efficiency. Common issues include restrictions in air flow, valve misalignment, and control system malfunctions. By systematically measuring air flow, power requirements, and temperature, these problems can be diagnosed.

For instance, a drop in power output may indicate an obstruction or malfunctioning valve that requires immediate attention.

Troubleshooting these air flow valve issues involves a combination of diagnostic techniques and preventive maintenance. Regular monitoring of performance metrics can provide early warning signs of impending failures. Additionally, ensuring that the valves are properly calibrated and free from debris can significantly enhance overall system efficiency.

Identifying and addressing these challenges not only improves the performance of the air flow system but also extends the lifespan of critical engine components.

Related Posts

-

Exploring Key Specifications for the Best Industrial Control Valves and How to Choose the Right One

-

How to Choose the Best Solenoid Valves for Your Industrial Applications

-

How to Choose the Right Diaphragm Valve for Your Industrial Applications

-

7 Effective Tips to Optimize Pneumatic Flow Valve Performance

-

Top 10 Applications of the Best Pneumatic Solenoid Valves in Industrial Automation

-

Understanding the Functionality of Diaphragm Flow Control Valves in Modern Applications