7 Effective Tips to Optimize Pneumatic Flow Valve Performance

Optimizing the performance of pneumatic flow valves is crucial for enhancing operational efficiency across various industrial applications. According to a recent report by Research and Markets, the global pneumatic valves market is projected to reach $7.5 billion by 2025, reflecting a growing demand for enhanced automation and control systems. As industries increasingly focus on improving their processes, the role of pneumatic flow valves becomes more significant, influencing not only the energy consumption but also the reliability of the entire system. Inefficient flow management can lead to increased operational costs and downtime, making it essential for engineers and technicians to adopt effective strategies that maximize the performance of these critical components. In this blog, we will explore seven actionable tips to ensure your pneumatic flow valves operate at their best, ultimately driving productivity and sustainability in your operations.

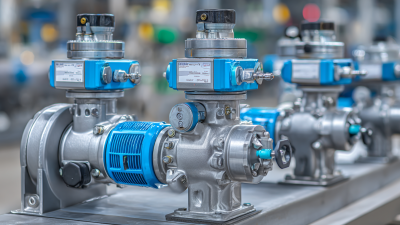

Understanding Pneumatic Flow Valves and Their Role in Systems

Pneumatic flow valves are essential components in various industrial systems, helping to regulate airflow and maintain system efficiency. Understanding their design and functionality is crucial for optimizing performance. These valves control the flow of compressed air, affecting the operation of machinery, automation systems, and other applications where precise air control is necessary. By ensuring a proper fit and efficient design, one can significantly enhance the overall effectiveness of these systems.

One effective tip for optimizing pneumatic flow valve performance is to regularly inspect and maintain the valves to prevent leaks and ensure smooth operation. Another crucial aspect is selecting the appropriate valve size; using a valve that is too small can restrict airflow, while one that is too large may lead to inefficiencies. Additionally, adjusting the valve's settings based on the specific application can help achieve precise control over air pressure and flow rates, improving system responsiveness and reducing energy consumption.

Analyzing Common Factors Affecting Valve Performance

When analyzing the common factors affecting pneumatic flow valve performance, it's essential to first consider the design and materials used in the valve itself. Variations in the construction materials can lead to differences in durability, resistance to corrosion, and overall efficiency. For example, using high-quality metals or polymers can enhance the valve's lifespan and reduce the risk of leaks, which is critical in maintaining optimal pneumatic system performance.

Another significant factor is the operating conditions, including pressure and temperature. Pneumatic valves are designed to operate within specific ranges, and exceeding these limits can compromise their functionality. Consistent monitoring of these parameters helps in adjusting and calibrating the system accordingly, ensuring that the valves perform efficiently over time. Additionally, regular maintenance is crucial, as accumulated debris and wear over time can impede valve operation. Implementing a standardized maintenance schedule can help in proactively addressing these issues, resulting in improved performance and reduced downtime.

7 Effective Tips to Optimize Pneumatic Flow Valve Performance

| Tip No. | Tip Description | Common Issues | Impact on Performance |

|---|---|---|---|

| 1 | Regular Maintenance | Wear and tear, dirt accumulation | Reduces efficiency and responsiveness |

| 2 | Proper Installation | Incorrect alignment, pipe strain | Causes leaks and potential failure |

| 3 | Use Quality Components | Low-grade materials | Increases the frequency of failures |

| 4 | Control Air Quality | Moisture and contaminants | Requires more frequent repairs |

| 5 | Optimize Valve Sizing | Under or oversized valves | Affects flow rates and system efficiency |

| 6 | Monitor Pressure Levels | Pressure spikes and drops | Reduces reliability and can damage valves |

| 7 | Regular Training for Operators | Lack of understanding of systems | Increases the chance of user error |

Best Practices for Regular Maintenance and Inspection

Regular maintenance and inspection are crucial for optimizing the performance of pneumatic flow valves. Implementing best practices not only enhances their efficiency but also extends their lifespan. One effective tip is to establish a routine inspection schedule. Just as maintaining a home involves regular health check-ups, ensuring that pneumatic systems are regularly inspected allows for the early detection of potential issues. This can prevent costly downtime and ensure smooth operations.

Another important practice is to keep the valves clean and free from debris. Contaminants can significantly impede performance, so incorporating a cleaning protocol within your maintenance routine is essential. Adopting a comprehensive maintenance checklist, similar to those used in other industries, can guide you in routinely checking all aspects of the pneumatic flow system. Additionally, engaging with qualified professionals for thorough inspections can result in better maintenance decisions and timely interventions. By prioritizing these best practices, you set your pneumatic systems up for success and reliability in their performance.

Innovative Technologies for Enhanced Valve Efficiency

In today’s industrial landscape, optimizing the performance of pneumatic flow valves is crucial for enhancing operational efficiency. Innovative technologies have emerged as game-changers, enabling businesses to achieve significant improvements in valve efficiency. According to a recent report by the International Society for Automation (ISA), the adoption of smart valve technology has led to an average 20% reduction in energy consumption across various sectors. This not only results in lower operating costs but also contributes to sustainability efforts by minimizing the carbon footprint.

One of the most impactful innovations is the integration of IoT and AI capabilities into valve systems. These technologies facilitate real-time monitoring and predictive maintenance, significantly reducing downtime. A study by the American Society of Mechanical Engineers (ASME) highlighted that companies utilizing predictive analytics for valve maintenance experienced a 30% increase in uptime compared to traditional methods. Additionally, advancements in materials, such as corrosion-resistant alloys, are enhancing valve durability, ensuring they perform optimally under varying pressure and temperature conditions. As industries continue to embrace these innovations, pneumatic flow valves will play an increasingly vital role in driving operational excellence.

Real-World Applications: Success Stories of Optimized Pneumatic Flow Valves

In the realm of industrial automation, optimizing pneumatic flow valves has become a vital focus for enhancing system efficiency and performance. Real-world applications showcase how companies have successfully improved their operations by implementing optimized flow valves. For instance, a textile manufacturing plant faced issues with inconsistent pressure levels, leading to production delays. By integrating advanced flow valves and fine-tuning their settings, the plant was able to create a more stable and efficient operation, significantly reducing downtime and improving overall output.

Another compelling success story comes from the automotive sector, where a major assembly line struggled with the rapid cycling of pneumatic actuators. The introduction of optimized pneumatic flow valves with precise control mechanisms allowed the line to achieve faster cycle times without sacrificing quality. This not only streamlined the production process but also resulted in notable cost savings and higher product throughput. These examples illustrate the transformative power of optimized pneumatic flow valves, demonstrating how strategic enhancements can directly contribute to operational success across varied industries.

Related Posts

-

The Definitive Guide to Sourcing Top Quality Small Pneumatic Valves from Trusted Suppliers

-

Exploring Innovative Alternatives to the Best Small Pneumatic Valves for Your Industrial Needs

-

2025 Market Trends in Pneumatic Valves for Global Buyers

-

How to Choose the Best Solenoid Valves for Your Industrial Applications

-

Top 10 Applications of the Best Pneumatic Solenoid Valves in Industrial Automation

-

Exploring Key Specifications for the Best Industrial Control Valves and How to Choose the Right One