Understanding the Functionality of Diaphragm Flow Control Valves in Modern Applications

In today’s rapidly evolving industrial landscape, efficient fluid management is crucial for the optimization of various processes. One of the key components that enhance fluid control capabilities is the diaphragm flow control valve. This innovative device plays a critical role in regulating fluid flow and maintaining system integrity across a multitude of modern applications, from water treatment facilities to chemical processing plants. By utilizing a flexible diaphragm to precisely modulate flow rates, these valves provide unparalleled accuracy and reliability. As industries increasingly prioritize sustainability and efficiency, understanding the functionality of diaphragm flow control valves is essential for engineers and operators alike. This blog will delve into the working principles, advantages, and real-world applications of diaphragm flow control valves, highlighting their significance as effective solutions for contemporary fluid management challenges.

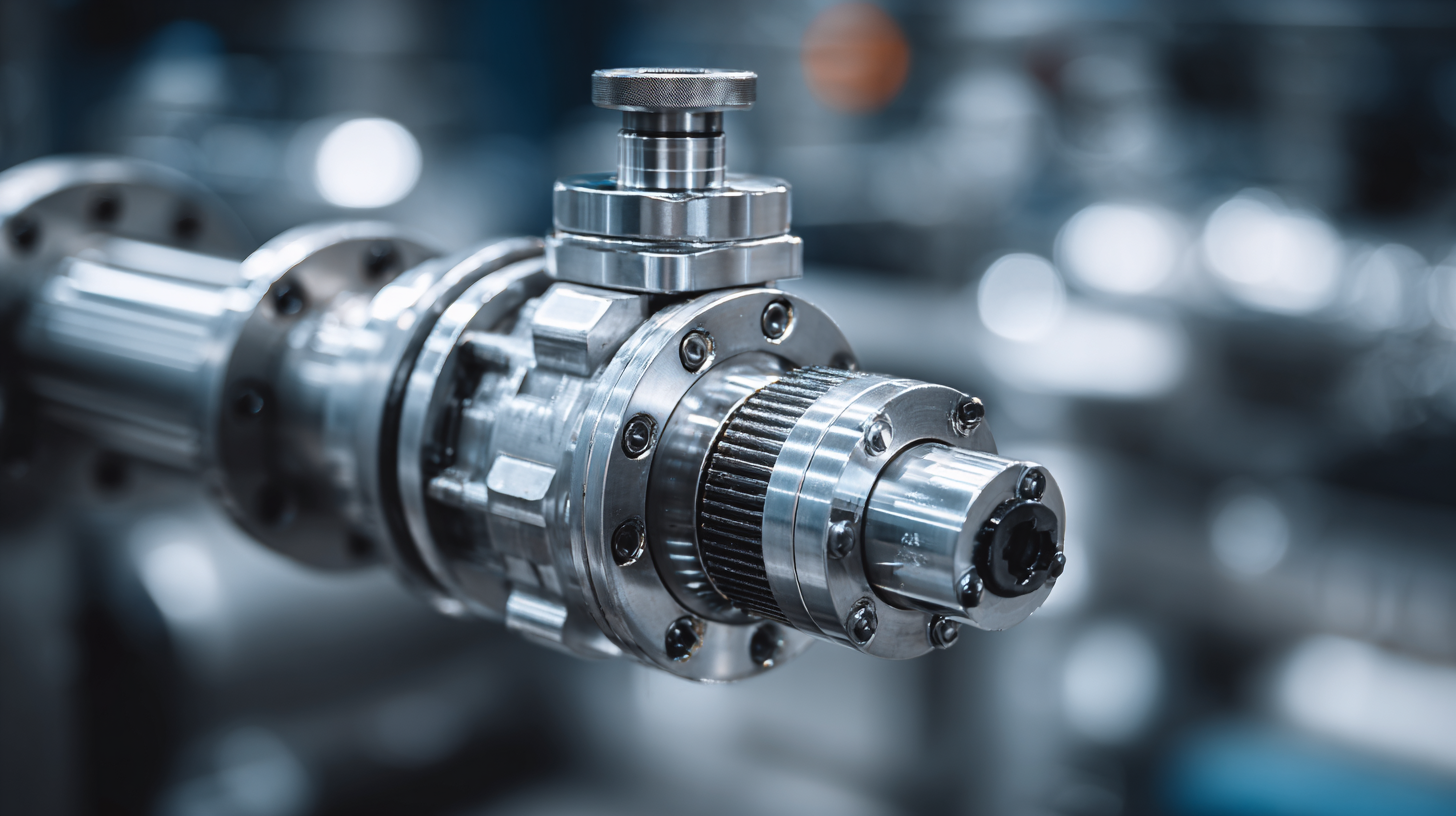

Key Characteristics of Diaphragm Flow Control Valves in Contemporary Systems

Diaphragm flow control valves are integral components in modern fluid handling systems, providing precision and reliability across various applications. One of the key characteristics of these valves is their ability to maintain consistent flow rates despite fluctuations in pressure. According to a report by the International Society of Automation, systems utilizing diaphragm valves can achieve flow consistency within ±2%, significantly enhancing operational efficiency in industries such as pharmaceuticals and food processing.

Another notable aspect is the diaphragm's material composition, which plays a crucial role in ensuring durability and compatibility with various media. Many contemporary diaphragm valves feature advanced elastomers and thermoplastics that can withstand harsh conditions while minimizing the risk of contamination. The Global Market Insights report indicates that the demand for such high-performance materials is expected to increase by approximately 6.5% annually, reflecting a growing need for reliable flow control solutions in critical applications. This shift underscores the importance of diaphragm flow control valves in enhancing system performance and safety.

Understanding the Functionality of Diaphragm Flow Control Valves in Modern Applications

| Characteristic | Description | Applications | Advantages |

|---|---|---|---|

| Pressure Management | Maintains consistent pressure levels in fluid systems. | Water treatment, chemical processing. | Improves system stability and safety. |

| Flow Regulation | Controls the rate of flow in pipelines. | Pharmaceuticals, food processing. | Enhances precision in fluid delivery. |

| Material Compatibility | Available in various materials for different media. | Oil & gas, water supply. | Reduces corrosion and extends valve life. |

| Leak-Free Operation | Designed to prevent leaks in various conditions. | Waste management, industrial applications. | Improves environmental safety. |

| Ease of Maintenance | Simple design allows for easy maintenance and replacement. | Manufacturing, HVAC systems. | Reduces downtime and maintenance costs. |

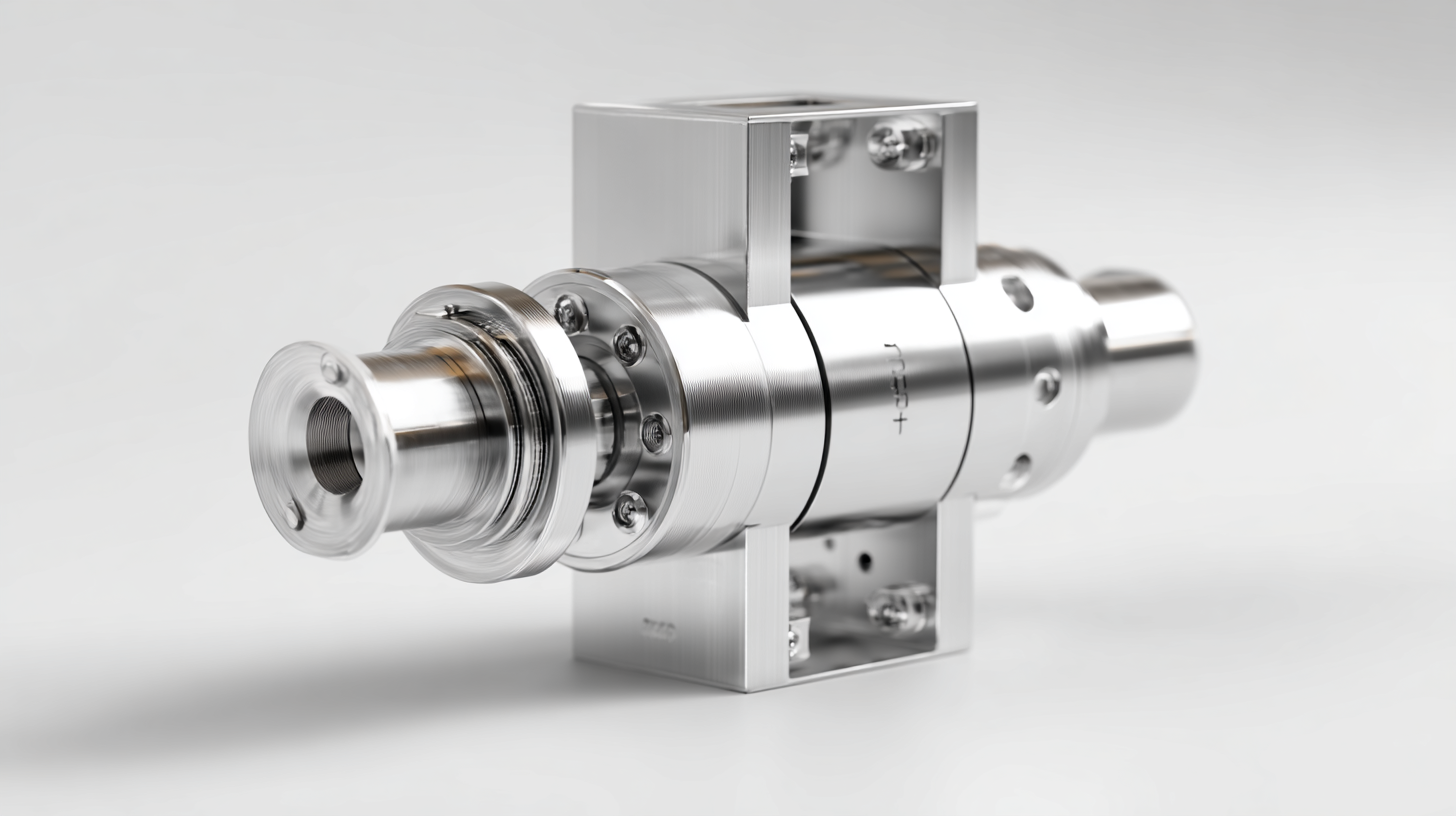

Advantages of Using Diaphragm Valves in Precise Flow Management

Diaphragm flow control valves have become increasingly popular in various industries due to their exceptional ability to provide precise flow management. These valves utilize a flexible diaphragm to regulate the flow of fluids, making them ideal for applications that require accuracy and control. The design allows them to handle different media, including corrosive fluids and slurries, all while minimizing leakage and ensuring consistent performance.

One significant advantage of diaphragm valves is their ability to maintain tight shut-off conditions. This feature is particularly valuable in applications where maintaining specific flow rates is critical, such as in pharmaceutical manufacturing or water treatment processes. The inherent flexibility of the diaphragm allows the valve to adjust smoothly to changes in pressure, ensuring dependable operation across various environments.

**Tip:** When selecting a diaphragm valve for your application, consider the material compatibility with the fluid being regulated. Using the right materials can significantly enhance the valve's longevity and performance.

**Tip:** Regular maintenance is crucial for diaphragm valves. Periodically inspect and replace the diaphragm as needed to prevent performance issues and ensure your flow management system operates efficiently over time.

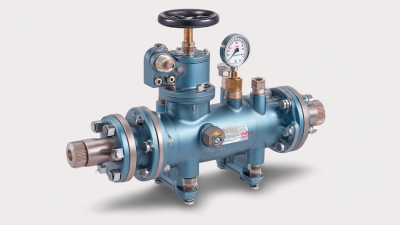

Comparative Analysis: Diaphragm Valves vs. Traditional Flow Control Solutions

Diaphragm flow control valves have become increasingly prominent in various industrial applications, especially when compared to traditional flow control solutions like globe or ball valves. According to a report by the Engineering Research Center,

diaphragm valves provide improved sealing characteristics

and reduced leakage rates, which can be critical in industries such as pharmaceuticals and food processing where sanitation is paramount. These valves are engineered with flexible diaphragms that regulate flow without direct contact

between the media and the valve components, minimizing contamination risks.

Diaphragm flow control valves have become increasingly prominent in various industrial applications, especially when compared to traditional flow control solutions like globe or ball valves. According to a report by the Engineering Research Center,

diaphragm valves provide improved sealing characteristics

and reduced leakage rates, which can be critical in industries such as pharmaceuticals and food processing where sanitation is paramount. These valves are engineered with flexible diaphragms that regulate flow without direct contact

between the media and the valve components, minimizing contamination risks.

In contrast, traditional flow control solutions often involve more intricate mechanisms that can increase wear and tear over time, leading to higher maintenance costs. A study published in the Journal of Process Engineering highlighted that

diaphragm valves require significantly less maintenance, with a 30% reduction in downtime as compared to conventional valve types. Furthermore, diaphragm valves offer a quicker response time

for flow adjustments due to their design, making them ideal for high-precision applications. As industries continue to prioritize both efficiency and safety,

the advantages of diaphragm flow control valves are becoming ever more apparent.

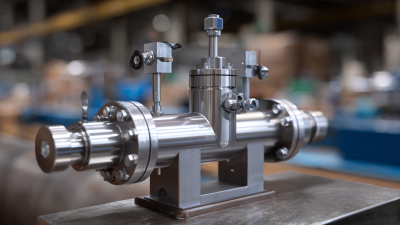

Applications of Diaphragm Flow Control Valves in Various Industries

Diaphragm flow control valves play a crucial role in a variety of industrial applications due to their precision and reliability in managing fluid flow. In the pharmaceutical industry, for instance, these valves ensure the safe and sterile transfer of liquids, enabling the production of high-quality medications. Their design minimizes contamination risks, making them ideal for processes that require strict hygiene standards. Additionally, diaphragm valves are often used in water treatment facilities, where they help regulate the flow of chemicals and water, ensuring optimal treatment processes while maintaining environmental safety.

In the food and beverage sector, diaphragm flow control valves are essential for controlling the flow of ingredients with varying viscosities. The robust design of these valves withstands fluctuations in pressure and temperature, which is vital for maintaining product integrity and taste. Furthermore, industries like chemicals and petrochemicals also benefit from diaphragm valves, as they can handle aggressive fluids and corrosive environments. This versatility across various sectors highlights the importance of diaphragm flow control valves in modern industrial applications, making them a trusted choice for effective fluid management.

Applications of Diaphragm Flow Control Valves in Various Industries

This chart illustrates the distribution of diaphragm flow control valve applications across different industries, highlighting their versatility and importance in modern systems.

Future Trends and Innovations in Diaphragm Flow Control Technology

As diaphragm flow control technology continues to evolve, the integration of MEMS (Micro Electromechanical Systems) presents a new realm of possibilities for enhancing performance and precision in various applications. The recent advancements in MEMS pressure sensors—ranging from micro differential pressure sensors to resonant pressure sensors—demonstrate a significant leap in functionality and miniaturization. These innovations allow for more compact and efficient diaphragm flow control valves, ultimately improving their responsiveness and accuracy in regulating fluid flow.

Future trends indicate a strong emphasis on creating smarter and more adaptable flow control solutions through the incorporation of advanced sensors and control algorithms. The capability to integrate MEMS components into diaphragm valves offers real-time monitoring and feedback mechanisms, enhancing the overall system performance. As industries seek to optimize efficiency and reduce waste, the role of such innovative technologies will be pivotal in meeting the increasing demand for precision in flow control applications. The intersection of diaphragm technology with MEMS holds the promise of not only improving existing systems but also paving the way for entirely new applications across various sectors.

Related Posts

-

Exploring Key Specifications for the Best Industrial Control Valves and How to Choose the Right One

-

2025 Market Trends in Pneumatic Valves for Global Buyers

-

Unlocking Precision in Fluid Dynamics with the Best Liquid Flow Control Valve Technical Specifications and Best Practices

-

Emerging Trends in Pressure Valve Technology for 2025 Shaping Industry Standards

-

The Definitive Guide to Sourcing Top Quality Small Pneumatic Valves from Trusted Suppliers

-

Exploring Innovative Alternatives to the Best Small Pneumatic Valves for Your Industrial Needs