7 Compelling Reasons to Choose Industrial Control Valves for Your Global Sourcing Needs

In the ever-evolving landscape of global manufacturing, the selection of the right components can significantly impact operational efficiency and cost-effectiveness. Among these crucial components, industrial control valves play a vital role, governing flow rates and pressure levels across various applications. According to a recent market analysis by Research and Markets, the global industrial control valves market is projected to reach $8.4 billion by 2025, growing at a CAGR of 5.5% over the next five years. This growth underscores the increasing demand for reliable control systems in industries such as oil and gas, water treatment, and chemicals. As companies strive to optimize their sourcing strategies, understanding the compelling reasons to choose industrial control valves becomes paramount for ensuring not only compliance and safety but also superior performance and sustainability in operational processes.

Key Benefits of Industrial Control Valves in Global Supply Chains

Industrial control valves play a pivotal role in enhancing the efficiency and reliability of global supply chains. One of the key benefits of these valves is their ability to regulate the flow of fluids and gases with precision. This not only optimizes processes but also helps maintain consistent product quality across various locations. By implementing industrial control valves, companies can ensure that every facet of their supply chain, from production to distribution, operates smoothly and efficiently, minimizing the risk of costly downtime.

Another significant advantage of industrial control valves is their adaptability to diverse environments and regulations. As businesses expand their operations internationally, they encounter varying standards and requirements. Industrial control valves are designed to meet these challenges, providing flexibility and compliance with local regulations. This adaptability not only simplifies the sourcing process but also enhances overall operational resilience, allowing companies to respond swiftly to market changes while maintaining high performance and safety standards in their supply chains.

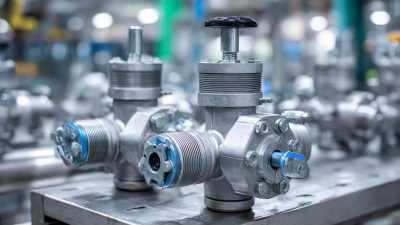

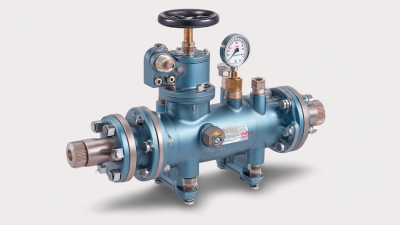

Understanding the Types of Industrial Control Valves for Optimal Sourcing

When sourcing industrial control valves for global needs, understanding the various types available is essential for optimal decision-making. Industrial control valves are integral in managing flow and pressure within various processes, and their classifications typically include globe, ball, butterfly, and gate valves. Each type serves distinct applications, and selecting the right one is critical to achieving efficiency and reliability in operations.

Globe valves are often favored in applications requiring precise flow regulation due to their ability to throttle flow effectively. On the other hand, ball valves are recognized for their quick operation, making them ideal for on/off control in high-pressure scenarios. Butterfly valves provide a lightweight option with a compact design, suitable for large volume flow control, while gate valves are perfect for fully open or closed operations, offering minimal flow resistance. By understanding these variations, companies can make informed choices that align with their operational requirements and sourcing strategies.

Globe valves are often favored in applications requiring precise flow regulation due to their ability to throttle flow effectively. On the other hand, ball valves are recognized for their quick operation, making them ideal for on/off control in high-pressure scenarios. Butterfly valves provide a lightweight option with a compact design, suitable for large volume flow control, while gate valves are perfect for fully open or closed operations, offering minimal flow resistance. By understanding these variations, companies can make informed choices that align with their operational requirements and sourcing strategies.

Criteria for Selecting the Right Industrial Control Valve Suppliers

When selecting the right industrial control valve suppliers, a few key criteria should guide your decision-making process. First and foremost, assess the supplier's reputation and experience in the industry. A well-established supplier with a proven track record can offer not only quality products but also valuable industry insights. Look for testimonials and case studies that showcase their ability to meet specific project requirements and maintain strong customer relationships.

Additionally, evaluate the technical support and customer service that the supplier provides. Access to knowledgeable support staff can be crucial, especially when navigating the complexities of industrial applications. Effective communication channels and prompt service can significantly impact project timelines and overall success. Finally, consider the supplier's ability to innovate and adapt to changing market conditions. A forward-thinking supplier will not only provide reliable products but also contribute to the long-term efficiency and sustainability of your sourcing strategy.

Cost-Effectiveness: How Industrial Control Valves Save You Money

When considering global sourcing needs, industrial control valves stand out for their remarkable cost-effectiveness. These valves not only provide reliable performance but also contribute significantly to cost savings across various operations. By opting for durable valves designed for longevity, businesses can reduce maintenance frequency and associated costs, which ultimately leads to higher profit margins.

Tip: Always evaluate the total cost of ownership rather than just the initial purchase price. A higher upfront investment in a quality valve may yield long-term savings through increased durability and fewer replacements.

Additionally, industrial control valves can optimize energy efficiency in your systems. By ensuring precise flow control, these valves help to minimize waste and reduce energy consumption, leading to further savings. The ability to maintain steady operational flows can significantly decrease operational disruptions and unexpected costs.

Tip: Conduct regular audits of your valve performance and energy usage to identify opportunities for efficiency improvements. Even minor adjustments can lead to substantial savings over time.

Improving Efficiency and Reliability with Quality Control Valves

In the modern industrial landscape, the push for efficiency and reliability has never been more critical. Quality control valves play a pivotal role in enhancing operational performance across various sectors, including the liquefied natural gas industry. According to recent studies, implementing high-quality control valves can reduce operational downtime by up to 20%, thereby significantly increasing productivity. These valves are designed to withstand harsh environments while maintaining precise flow control, which is essential in processes that demand high reliability.

**Tip 1:** When sourcing industrial control valves, prioritize those with certifications meeting international standards. This ensures that the valves can perform under extreme conditions and adhere to safety regulations.

Furthermore, as the production lines evolve, the integration of smart technologies has become prevalent. For instance, the introduction of advanced air valve technology has shown to improve infrastructure reliability in sewage management. Enhanced automation coupled with effective quality control mechanisms can result in a 15% reduction in maintenance costs by preemptively addressing potential failures.

**Tip 2:** Regularly assess the performance of your control valves. Monitoring their operational efficiency can help identify wear and tear early, avoiding costly breakdowns.

Incorporating quality control valves into your sourcing strategy not only optimizes operational efficiency but also contributes to enhanced reliability, positioning businesses to thrive in a competitive market.

Related Posts

-

Exploring Key Specifications for the Best Industrial Control Valves and How to Choose the Right One

-

Essential Factors to Consider When Selecting the Best Pneumatic Control Valve

-

Emerging Trends in Pressure Valve Technology for 2025 Shaping Industry Standards

-

The Definitive Guide to Sourcing Top Quality Small Pneumatic Valves from Trusted Suppliers

-

Understanding the Functionality of Diaphragm Flow Control Valves in Modern Applications

-

Exploring Innovative Alternatives to the Best Small Pneumatic Valves for Your Industrial Needs