How to Choose the Best Solenoid Valves for Your Industrial Applications

In the ever-evolving landscape of industrial automation, solenoid valves play a crucial role in the effective control of fluid and gas systems. According to a recent report by MarketsandMarkets, the global solenoid valves market is projected to reach approximately $4.2 billion by 2025, driven by increasing demand for automation in various sectors such as oil and gas, water treatment, and manufacturing. Choosing the right solenoid valves for your specific industrial applications is essential for optimizing performance and ensuring reliability. With a wide range of options available from the best manufacturing plants in China, it is important for professionals to understand key factors such as valve type, material compatibility, and operational parameters to make informed decisions. This article will guide you through the critical considerations in selecting the best solenoid valves to enhance the efficiency and effectiveness of your operations.

Benefits of After-Sales Service for Solenoid Valves in Industrial Settings

After-sales service is an essential aspect to consider when choosing solenoid valves for industrial applications. These components play a critical role in controlling fluid movement, and their reliability is paramount for the efficiency of various systems. A robust after-sales service ensures that any issues or malfunctions can be addressed promptly, minimizing downtime and maintaining productivity. Real-time support, replacement parts availability, and expertise can significantly enhance the longevity and performance of solenoid valves in industrial environments.

Moreover, comprehensive after-sales services often include maintenance checks and troubleshooting guides, allowing operators to perform routine inspections and mitigate potential problems before they escalate. With industries increasingly relying on advanced technologies, having support from manufacturers can facilitate smoother operations and help businesses stay ahead of the competition. By prioritizing suppliers who offer reliable after-sales service, companies can invest in solenoid valves that not only meet their immediate operational needs but also provide peace of mind for the future.

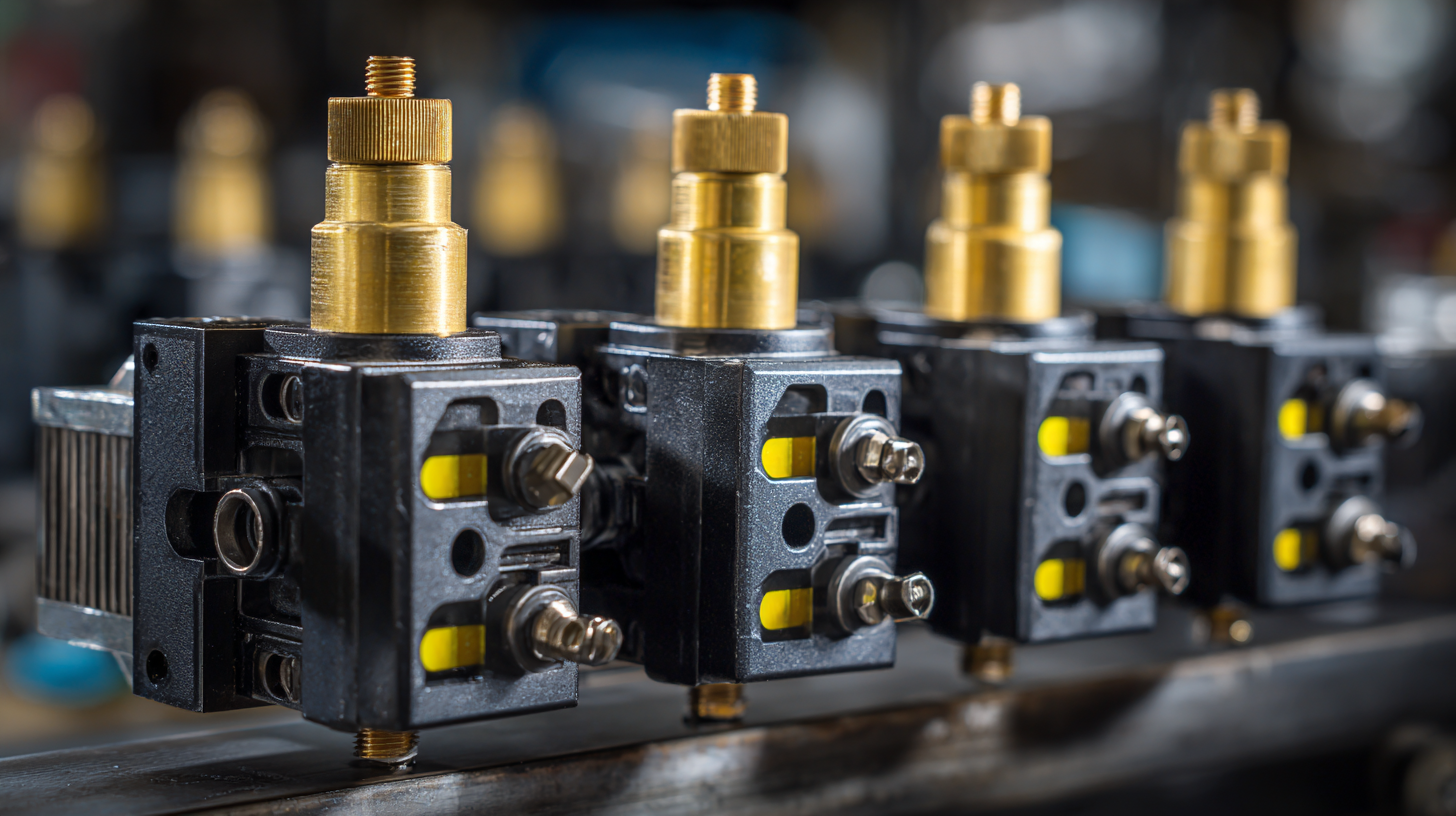

Understanding Repair Costs and Maintenance for Solenoid Valves

When selecting solenoid valves for industrial applications, it's crucial to consider not only their functionality but also the associated repair costs and maintenance requirements. Solenoid valves, while generally robust, can experience wear and tear over time due to factors such as fluid contamination, pressure fluctuations, and environmental conditions. Understanding these potential issues can help in budgeting effectively for repairs and downtime, which can significantly impact overall operational efficiency.

Regular maintenance is key to prolonging the lifespan of solenoid valves. This includes routine inspections, cleaning, and timely replacement of worn parts. Implementing a proactive maintenance schedule can prevent costly unplanned repairs and ensure smooth operations. Additionally, it’s wise to evaluate the availability of replacement parts and service support when selecting solenoid valves, as this can influence repair costs and lead times. By taking these factors into account, businesses can make informed decisions that align with their operational needs and financial strategies.

Maintenance Costs of Solenoid Valves Over Time

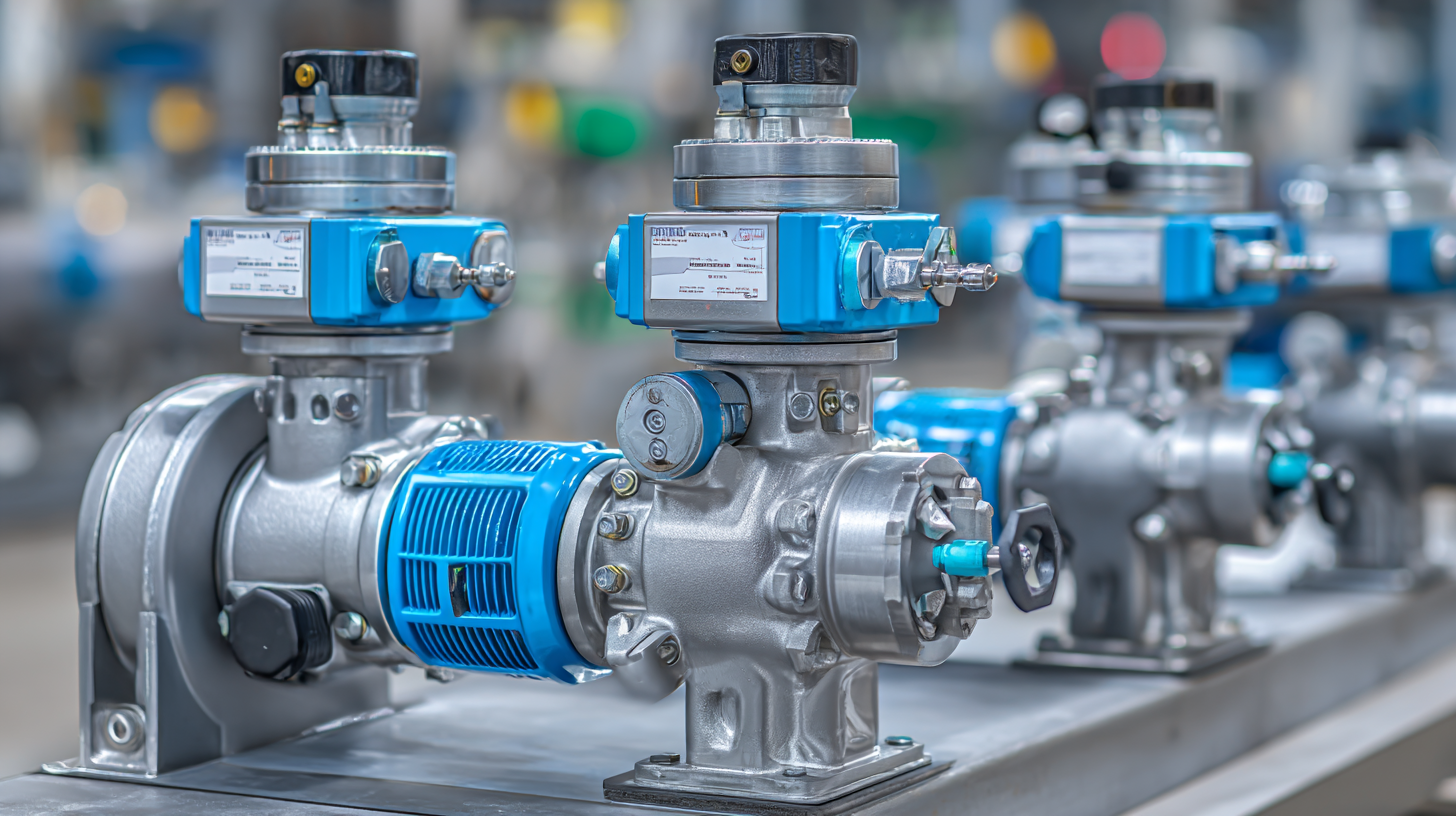

Key Features to Consider When Selecting Solenoid Valves

When selecting solenoid valves for industrial applications, it’s crucial to consider several key features to ensure optimal performance and reliability. One of the primary factors is the valve's operating pressure range. Different applications may require valves that can handle varying levels of pressure, so it's essential to match the valve specifications with the system requirements. Additionally, consider the fluid type involved. Solenoid valves are made from various materials, and the compatibility of the valve with the fluid is critical to prevent degradation or leaks.

Another important feature to consider is the valve's response time and flow rate. The speed at which a valve opens and closes can significantly affect the efficiency of the application. For processes that require quick cycle times, selecting a valve with a fast response is paramount. Furthermore, the flow rate should align with the demands of your system to avoid bottlenecks or inefficient operation.

Lastly, environmental factors, such as temperature and potential exposure to corrosive substances, should influence your choice, ensuring that the chosen solenoid valve can withstand the specific conditions of its operating environment.

How to Evaluate Supplier Support for Your Solenoid Valve Needs

When selecting solenoid valves for industrial applications, evaluating supplier support is crucial. A reliable supplier not only provides quality products but also offers comprehensive support throughout the procurement and maintenance processes. According to Deloitte's recent research on evolving manufacturing supply chains, suppliers should demonstrate adaptability in the face of disruptions, ensuring consistent availability of essential components. This is particularly important when considering the performance of thermoplastic valve bodies, which provide enhanced properties due to their manufacturing process. A supplier's ability to maintain stock levels and provide timely delivery can significantly impact operational efficiency.

**Tip**: When assessing potential suppliers, look for those with proven track records in managing supply chain challenges. Research customer feedback and industry reports to gauge supplier reliability and responsiveness.

Additionally, effective communication channels should be a hallmark of a strong supplier relationship. Suppliers who engage with their customers through technical support and regular updates on product enhancements show a commitment to meeting clients' evolving needs. Moreover, it's essential to evaluate the supplier's understanding of industry trends and innovations, which can lead to better product performance and integration into existing systems.

**Tip**: Prioritize suppliers who provide educational resources and technical assistance, as this can streamline the installation and maintenance processes, ultimately reducing downtime.

Tips for Ensuring Optimal Performance of Solenoid Valves in Applications

When selecting solenoid valves for your industrial applications, ensuring optimal performance is critical. One key factor to consider is the valve's compatibility with the fluid in which it will operate. Different fluids, be they gas or liquid, can have varying effects on materials used in the valve construction. Ensure you choose valves made from suitable materials that can withstand the corrosive nature or temperature of the fluids involved.

Additionally, understanding the valve's duty cycle is essential; ensure the solenoid can handle the frequency of operation required for your specific application.

Additionally, understanding the valve's duty cycle is essential; ensure the solenoid can handle the frequency of operation required for your specific application.

Another important aspect is the voltage rating of the solenoid. Matching the voltage of the solenoid valve with your system not only ensures reliable operation but also prevents overheating and potential failure. Moreover, consider the valve's response time and actuation speed, which are crucial in applications where precision is key.

Regular maintenance checks, including cleaning and testing, are also vital for maintaining optimal performance and prolonging the lifespan of solenoid valves. By addressing these factors, you can enhance the efficiency and reliability of solenoid valves in your industrial processes.